Connecting and Measuring

The following chapter details how to connect to a device, read data from the device, manually controlling the potential, run measurements on the device and finally how to properly close a connection to a device.

The pypalmsens top-level module contains all the relevant functions and classes for discovering and controlling instruments.

The InstrumentManager() and InstrumentManagerAsync() class are wrappers around our .NET libraries which make it possible to connect to and control PalmSens instruments from Python.

|

Mains Frequency

To eliminate noise induced by other electrical appliances it is highly recommended to set your regional mains frequency (50/60 Hz) in the general settings when performing a measurement |

Connecting to a device

The recommended way to connect to a device for most workflows is to use the pypalmsens.connect() context manager. The contextmanager manages the connection, and closes the connection to the device if it is no longer needed. It returns an instance of InstrumentManager(), which can be used to control the instrument and start a measurement:

>>> import pypalmsens

>>> with pypalmsens.connect() as manager:

... measurement = manager.measure(method)By default, connect() connects to the first instrument it discovers. With only one device connected, this is fine. With more than one instrument connected, you can use pypalmsens.discover() to find all devices and manage them yourself. For example, this is how to get a list of all available devices, and how to connect to the first one.

>>> available_instruments = pypalmsens.discover()

>>> available_instruments

[Instrument(name='EmStat4 HR [1]', connection='usbcdc', device=<PalmSens.Windows.Devices.USBCDCDevice object>)]

>>> first_instrument = available_instruments[0]

>>> with pypalmsens.connect(first_instrument) as manager:

... measurement = manager.measure(method)Finally, you can set up the InstrumentManager() yourself.

>>> import pypalmsens

>>> available_instruments = pypalmsens.discover()

>>> manager = pypalmsens.InstrumentManager()

>>> manager.connect(available_instruments[0])The InstrumentManager.disconnect() function disconnects from the device freeing it up for other things to connect to it.

>>> manager.disconnect()Currently PyPalmSens supports discovering instruments connected via FTDI, serial (usbcdc/com), and Bluetooth (classic/low energy). By default scanning with Bluetooth is disabled.

You can enable scanning with Bluetooth by setting:

>>> pypalmsens.discover(bluetooth=True)Manually controlling the device

Depending on your device’s capabilities it can be used to set a potential/current and to switch current ranges.

The potential can be set manually in potentiostatic mode and the current can be set in galvanostatic mode.

The following example show how to manually set a potential, for more examples refer to the ManualControlExample and ManualControlExampleAsync scripts included with the SDK.

>>> manager.set_potential(1)Measuring

Starting a measurement is done by sending method parameters to a PalmSens/Nexus/EmStat/Sensit device.

The InstrumentManager.measure() method returns a Measurement objcet and also supports keeping a reference to the underlying .NET object.

For more information please refer to PalmSens.Core.dll.

The following example runs a chronoamperometry measurement on an instrument.

>>> method = methods.chronoamperometry(

... interval_time=0.01,

... e=1.0,

... run_time=10.0

... )

>>> measurement = manager.measure(method)Callback

It is possible to process measurement results in real-time by specifying a callback on the InstrumentManager/InstrumentManagerAsync either by providing it as an override when it is created using the new_data_callback argument:

>>> def new_data_callback(new_data):

... for point in new_data:

... print(point)

...

>>> manager = instruments.InstrumentManager(

... callback=new_data_callback

... )or by setting it on the InstrumentManager’s callback field.

>>> with pypalmsens.connect() as manager:

... manager.callback = stream_to_csv_callback(csv_writer)The callback is passed a collection of points that have been added since the last time it was called. Points contain a dictionary with the following information:

- Non-impedimetric techniques

-

Techniques such as linear sweep voltammetry or chronopotentiometry return a dictionary containing the following values:

-

index: the index of the point -

x,x_unitandx_type; depending on the technique this will be:-

Time in seconds for amperometry and potentiometry techniques that do not specify a begin and an end potential

-

Potential in volts for voltammetry techniques such as linear sweep, cyclic and square-wave voltammetry

-

Current in micro amperes for linear sweep potentiometry

-

-

y,y_unitandy_type; depending on the techniques this will be:-

Current in micro amperes for all potentiometric techniques such as linear sweep and cyclic voltammetry and chronoamperometry and multistep amperometry

-

Potential in volts for all galvanostatic techniques such as chronopotentiometry and linear sweep potentiometry

-

-

- Impedimetric techniques

-

The exception are (galvanostatic/) electrochemical impedance spectroscopy. These techniques return the following:

-

frequency: the applied frequency of the sample in hertz -

z_re: the real impedance in ohms -

z_im: the imaginary impedance in ohms

-

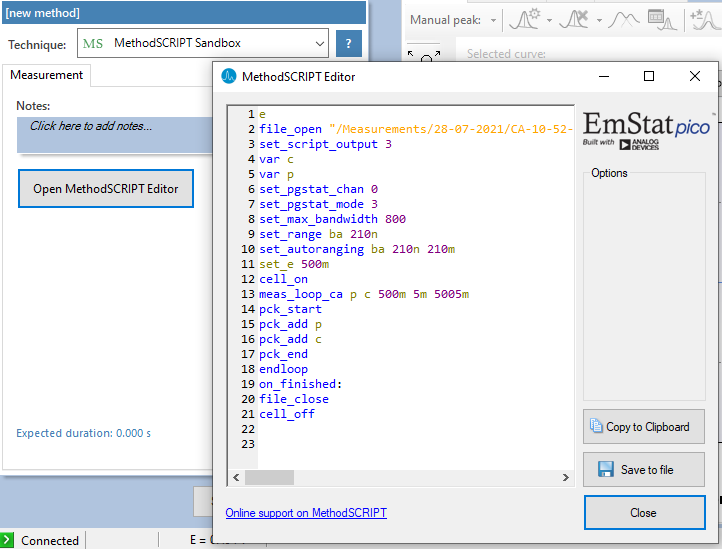

MethodSCRIPT™

The MethodSCRIPT™ scripting language is designed to integrate our OEM potentiostat (modules) effortlessly in your hardware setup or product.

MethodSCRIPT™ allows developers to program a human-readable script directly into the potentiostat module by means of a serial (TTL) connection. The simple script language allows for running all supported electrochemical techniques and makes it easy to combine different measurements and other tasks.

More script features include:

-

Use of variables

-

(Nested) loops

-

Logging results to an SD card

-

Digital I/O for example for waiting for an external trigger

-

Reading auxiliary values like pH or temperature

-

Going to sleep or hibernate mode

See the MethodSCRIPT™ documentation for more information.